→→onze medewerkersonze medewerkerswo

|

T +32 (0)56 50 30 71

VAT BE 0425.328.370 |

|

© 2024, DB Hardwoods nv |

|

DB Hardwoods nv Roeselarestraat 154 B-8880 Rollegem-Kapelle |

Rubberwood, the "all-round" hardwood:

The eco-friendly timber from the Rubberwood plantations.

|

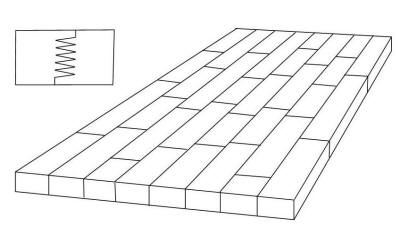

Rubberwood is one of the most ecological wood species. The wood of the rubbertree is only used after the full cyclus of latexproduction is finished. Rubberwood is an all-round hardwood : beautiful light-coloured texture, suitable strength, excellent machining properties and very stable.

For our SUPERIOR Quality, we only use the clear light colour and we select 2 sides AA quality. |

Range:

SUPERIOR quality : only light colour and 2 sides AA

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Quality of DB Hardwood SUPERIOR Rubberwood panels:

DB Hardwoods imports rubberwood panels since 1995.

In 2001 we started our own production unit in S.E.-Asia, to be no longer dependent of the variating quality of different producers.

This allowed us to create our unique SUPERIOR quality : only clear light colour and 2 sides AA quality.

Only 20% of the wood is used, the 80% balance is sold locally.

Until today we are still the only producer of SUPERIOR quality in Rubberwood panels.

Other qualities

In the mean time, we also have other qualities available in stock, in answer to our customers' needs.

These qualities are produced in the same production unit as the SUPERIOR quality.

1 FACE quality is used as alternative for SUPERIOR quality for applications where price is more important and where the quality of the back side is less important (B-quality).

CONSTRUCTION quality is used for invisible constructions, where the strength of the hardwood is important.

|

1 FACE quality

Technical same production but different quality selection :

Topside : A-quality

Backside : B-quality

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

CONSTRUCTION quality

Budget quality used for invisible applications, technically well made, knots, black spots tolerated |

|

||||||||||||||||||||||||

You can buy per full bundle, mixed bundle or by panel, in function of your needs.

Ask your price info@dbhardwoods.com

Pls mention the thickness, size and number of panels.

- perfect technical production.

- the panels are kiln dried 10 % (+/- 2 %)

- lamellas in average 45mm wide (35-58), uniform per panel

- perfect fingerjoint on the side of the panel, so you can only see right lines on the top and bottom side of the panel.

- glue is form Akzo Nobel, D4 waterresistant

- both sides sanded 180 G

- plastic packing for each panel individually or by bundle, protected against damage and moisture

|

Documentation Rubberwood Panels

|

Large stock in standard sizes:

With more than 5000 m3 permanent landed stock in Belgium, we can guarantee consistant quality,

short lead time and continuity in our supply.

STOCK IN ROLLEGEM-KAPELLE

Customized panels:

Rubberwood is one of the most used woodspieces for making staircases.

We also offer customized panels from 5 à 10 m3.

Everything is possible:

- every thickness between 15 and 63 mm

- every width till 1100 mm (max 1210 mm)

- every length till 5100 mm

finished parts : sanded components, profiled, with bevel, with radius, ...

In our factory we have a finishing line for the production of finished parts

for example :

- steps 30 x 290 x 900 / 4500 mm with 4 x chamfer 3 mm

- hand rails 45 x 70 x 4500 with 2 x R12,5 - 2 x chamfer

- counter boards 16 x 218 x 4500 1 x R8

- newel posts 70 x 70 x 4800 with 4 x chamfer 3 mm

delivery time : approx. 12-14 weeks

guarantee of quality and finishing

Many manufacturers (staircase manufacturers) can confirm the quality and precision of our products

Advantages of panels:

Panels are a standardized, ready-to-use product with several advantages:

- exact calculation of cost, no surprises

- very high efficiency

- less labour and machine-costs

- huge time saver

- simplicity of work

- easy and safe to store

Reasons to work with DB Hardwoods :

- manufacturer with constant large stocks and short lead times > you only buy what you need.

- very large range of thicknesses and dimensions.

- very competitive prices for a top quality.

- we are flexible and correct. We think with you to reduce costs and solve problems.

- you are buying from us security, with peace of mind

|

|

Finishing:

To give Rubberwood a beautiful finish, different finishing products were developped (oil, varnish, ...).

The most important thing to do before finishing is the sanding : you get the best result by using

isanding product based on silicium.

This grain remains sharp and avoids hairy finish after treatment.

Origin:

"What is rubberwood?" e.g. availability, ecological and social aspects

"Properties of rubberwood" e.g. woodworking, drying, staining, treatment

Ecology:

Ecology: Rubberwood respects the environment

Ecology: Rubberwood among best timbers in Greenpeace Good Wood Guide

Some applications and ideas:

Rubberwood panels are frequently used for maiking staircases, tables, furniture, customized applications, doorframes,

interiors of hotels, restaurants, pubs, shops, bathrooms, kitchens, interiors,...

In short : everyting that can be made in solid wood.

staircases:

A big sized panel on the panelsaw : 4 cuts and you have 2 sides and 15 steps !

first quality wood, no checks, no knots, no discoloration, ...

net usable wood, no waste, ... = low material cost

But the most important argument are the savings in labour cost

cutting, moulding, laminating, sanding, almost completely saved

Our panels have a length of 4m50 and a width of 1m10 :

- long enough for the longest side

- long enough for 5 steps of average 90 cm long

For the sides and the steps

- 33 mm is mostly used for closed steps (= finished "6/4" or 40 mm)

- 40 mm for more solid steps

- 44 mm for open staircases (= finished "8/4"or 50 mm)

- 51/56/63 mm for very heavy stairs or to be used for the exterior side

For the counterboards

- 15, 18 or 22 mm

For the newell posts, hand rails

- laminated squares 70x70 or 85x85 in length of 4000/4500 mm

The stairs can be finished in the same colour as the doors or the flooring,

simply by adding some colour in the first layer of varnish.

Finish can be light : natural, white wash, ...

or darker tones : merbau, oak, mahogany, wenge, ...

Offer your customer an alternative in ecological Rubberwood !

Because of the stability of rubberwood and the guaranteed lamination of the

panels,

the rubberwood panels are very suitable to make wooden steps on metal

staircases.

Even steps which are not holden in the sides, the steps will

remain stable. Customer can choose the finish in function of his interior.

We also have panels in Oak an Beech always with or without fingerjoint.

Do you have pictures of projects in rubberwood? We happily publish them on our website. Please mail us a copy on info@dbhardwoods.com

Doorframes :

Rubberwood panels are ideal to saw fast and with high yield solid doorframes.

In the past a lot of tropical timber was used. But not easy to get only door lengths.

And a lot of work : sawing, moulding, glueing, sanding, ...

Now you can saw easily the widths you need out of a sanded panel of 1m10 wide.

Perfectly dried, stable, no splits, ...

Mosst used is 40 mm and 44 mm thickness, 51, 56 and 63 mm are also available.

Standard stock lengths is 4500 mm (2 x length of a door), but we also have 5100 mm in 40, 51 and 63 mm for longer doors

and in 40 and 44 mm in length 2m50

Customized work possible from 5 m3. For example length of 2180, 2700, 4500 mm

Furniture

Rubberwood is a very valuable hardwood for making furniture.

It is clear that in Europe, with our labour costs, we cannot make kitchen trolleys, salad bowls or cutting boards.

On the other side, not all furniture will be made by thousands sets in low cost countries. Also transport cost of all furniture which is not knockdown, is very expensive and rising.

With our rubberwood boards, you can produce solid wood style and design furniture in a very interesting way.

We supply finished, sanded panels in 1st quality, ready to use at very interesting prices. You design the style and models which are doing well in your market.

The production is totally under your own control, in your own factory, but at much lower cost than normal : very important savings in labour and machine cost, because the most labour intensive works (cutting, moulding, selecting, laminating, sanding, ...) are done elsewhere.

You receive a half-finished product that can be directly integrated in your production process.

Less machines, less energy costs, less storage costs, less costs for waste and sawdust.

The most important is the finish. Rubberwood has a light colour and can easily be finished in any other stain.

It is often better to give a modern trendy finish than using the natural finish, which reminds too much of cheap imported furniture sets.

Rubberwood is an all round solid wood, which can easily be finished : white wash, light or dark cherry, modern or rustic oak, walnut, wenge, colonial, ...

The result is beautiful, solid wood furniture, in the design adapted to your

country, in the colour that your customers like and MADE IN EUROPE.

Rubberwood is also often used to make furniture components in solid wood. Shelves, sides and backs of furniture, legs, ...

Normal thickness is 15, 18, 22, 24, 30, 33, 40, 44, 51, 56 and 63 mm panels.

You can work in standard panels (1100 x 4500 mm) available in stock or we can deliver panels on your sizes, with a lead time of abt 12-14 weeks

This furntiure is fully made out of rubberwood panels.

A lot of furniture companies have

developed models starting from rubberwood panels, but they commercialise them under another species name. Also a lot of models are protected and we cannot put pictures on our website. Please call us if you want to know more.

We also have panels in Oak an Beech always with or without fingerjoint.

Do you have pictures of projects in rubberwood? We happily publish them on our website. Please mail us a copy on info@dbhardwoods.com

Tables

Because of the stability of rubberwood, it is ideal for solid tabletops. The main advantage is that you start from a finished panel to make the table top ! Only cut to size and finish the sides.

The finish and colour can be choosen, as rubberwood is easy to stain and finish : natural, white wash, dark or light cherry, modern or rustic oak, walnut, wenge, ...

There is a big demand for strict lines, for which large laminated panels are very suitable. You can use panels in 33 or 44 mm or other thickness.

Also, we have a wide range in surfaced tablelegs, available in stock, including heavy sized tablelegs such as 115x115x740

We also have panels in Oak and Beech always with or without fingerjoint.

Do you have pictures of projects in rubberwood? We happily publish them on our website. Please mail us a copy on info@dbhardwoods.com

Interiors of hotels, bars, restaurants, cafés,...

Made to order furniture for hotels, restaurants, cafés, ...

Especially in the contract furniture business solid wood is very much appreciated.

In labour time it is cheaper to work with solid wood tops, than starting from particle board, plywood or MDF and then put veneer or melamine on each sheet, glue solid bands on the sides ...

Also solid wood is much more hygienic and casual damage can easily be repeared. With veneered sheets this is difficult.

Main use is 30 mm thickness. We offer 3 widths out of inventory : 710 - 810 - 1210 mm Length : 3650 mm (multiple of 60 cm per person, 3 x 1210 mm or 5 x 710 mm)

Solid table tops were taboo for many people : too risky and too expensive. Try our rubberwood and you will ask yourself why you didn't start earlier. 100% guarantee of the lamination : you will never have problems

We also have a range of solid table legs in inventory.

The biggest argument to your customer : beautiful solid wood table tops in the colour that he likes, in harmony with his interior or the atmosphere he wants to create. Often the colour will be the same colour as the chairs.

We also have panels in Oak, Beech and Ash, always with or without fingerjoint.

Do you have pictures of projects in rubberwood? We happily publish them on our website. Please mail us a copy on info@dbhardwoods.com

Also the barfurniture, cabinets, seats, grills, ... can be made in the same big panels in the same colour as the table tops.

Large error-free panels to work out all your client wishes in solid wood.

Kitchens and bathrooms

Wood is a product of nature and gives warmth and charm to your kitchen. Solid wood gives life to you interiors.

A lot of peope are afraid to use solid wood. Indeed, some wood species easily split or distort, certainly when water is envolved.

Rubberwood, however, is a very stable wood and gives no problems for kitchen tops, under the condition that you put some protection,

all around on the wood : varnish or oil.

You can put some varnish with colour and finish with the usual end layers. Or you can use oil, which can be repeated to have permanent protection.

These panels are also very easy to use for making kitchen cabinet doors, shelves, cupboards, ...

We also have panels in Oak, Beech and Ash, always with or without fingerjoint.

Do you have pictures of projects in rubberwood? We happily publish them on our website. Please mail us a copy on info@dbhardwoods.com

Shop and interior fittings

In modern interiors there is a lot of "made to order". It is trendy to combine different materials (wood, metal, glass,...)

Solid wood always give a plus to interiors.

The large dimensions and 10 different thicknesses make plenty of possibilities for bespoke furniture : counters, cabinets, displays, decks, bookcases, school furniture, church furniture, ...

You always start from a finish product : cut to size and stain.

Making a shelve of 4m50 long ? Piece of cake.

Making a special shaped computer desk ? Piece of cake.

Making a special cabinet ? Piece of cake.

We also have panels in Oak, Beech and Ash, always with or without fingerjoint.

Do you have pictures of projects in rubberwood? We happily publish them on our website. Please mail us a copy on info@dbhardwoods.com